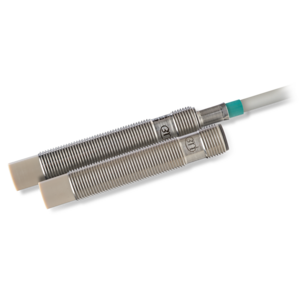

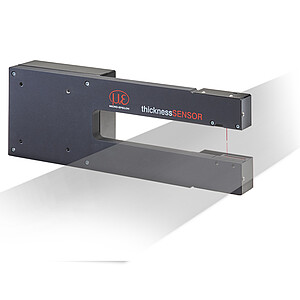

Capacitive sensors from Micro-Epsilon are robust and achieve submicron resolution in industrial applications. Therefore, they are often used for applications that require the highest precision and stability. Based on an innovative sensor design, accessories and powerful multi-channel controllers, they perform extremely well in precise thickness measurements of battery films.

Capacitive thickness measurements for battery film

High precision thickness measurements of battery films

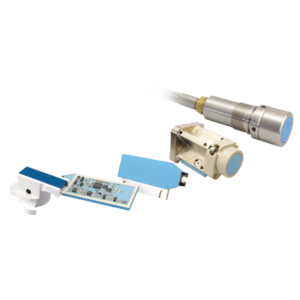

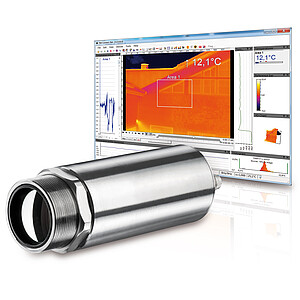

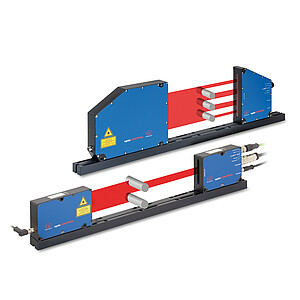

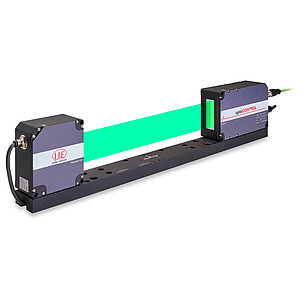

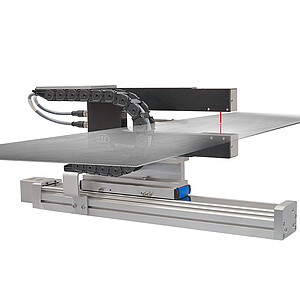

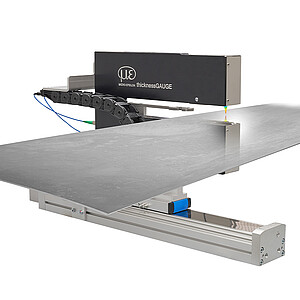

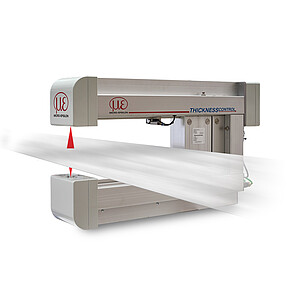

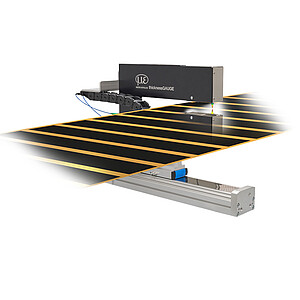

In order to determine the thickness of battery films with high accuracy, capacitive sensors are used directly in the production line. For this purpose, the sensors are attached to a measuring bracket and measure onto the film from two sides. Each of the two capacitive displacement sensors delivers a high-resolution distance signal, which is directly processed in the DT6200 controller as a thickness measurement value. Since the measurement spot of the sensors is larger than with optical measuring methods, structures and anomalies on the surface are averaged. Due to their high temperature stability, the sensors provide stable measurement values even with fluctuating ambient temperatures.

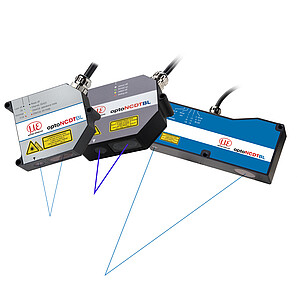

For precise thickness measurements, the innovative capaNCDT 6200 multi-channel controller is used. It detects, processes and evaluates values from up to four channels simultaneously. For fast measurements up to 20 kHz, the capaNCDT 6222 multi-channel system is used.